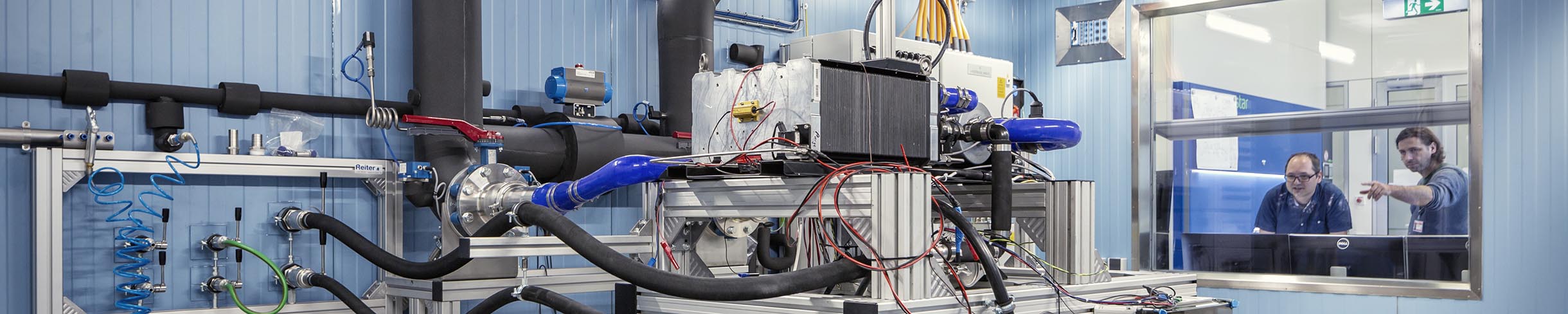

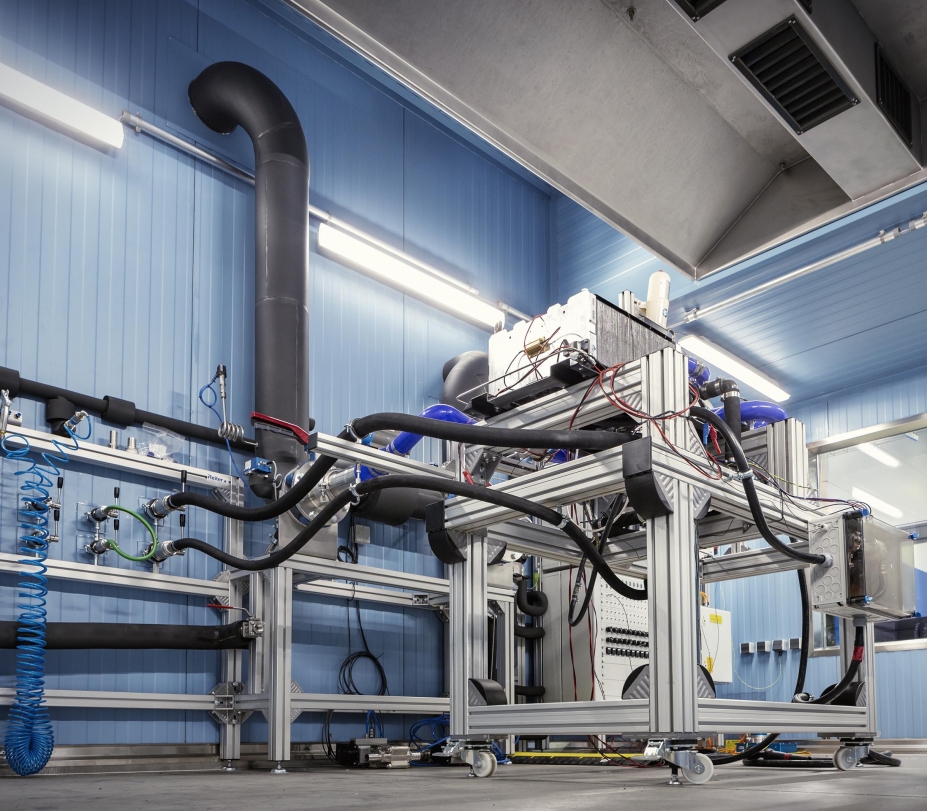

fuel cell test bed

Under all conditions

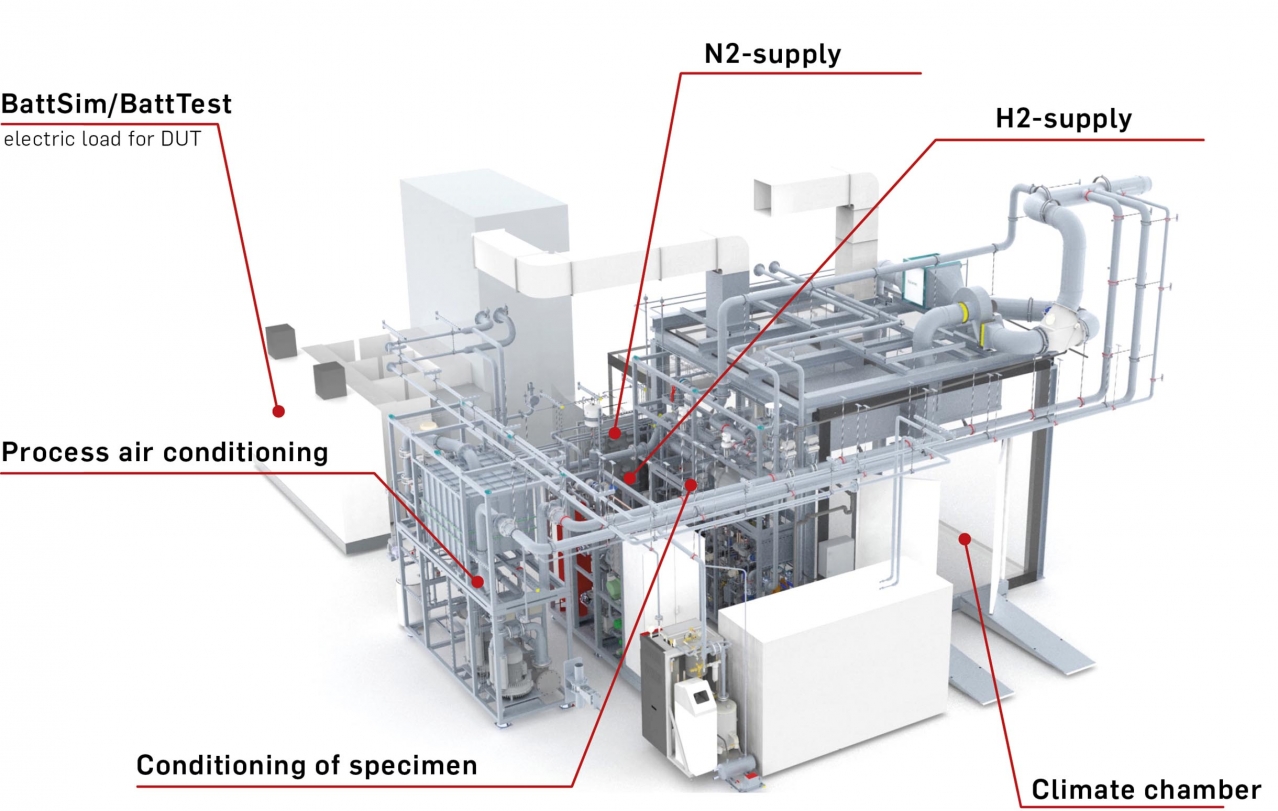

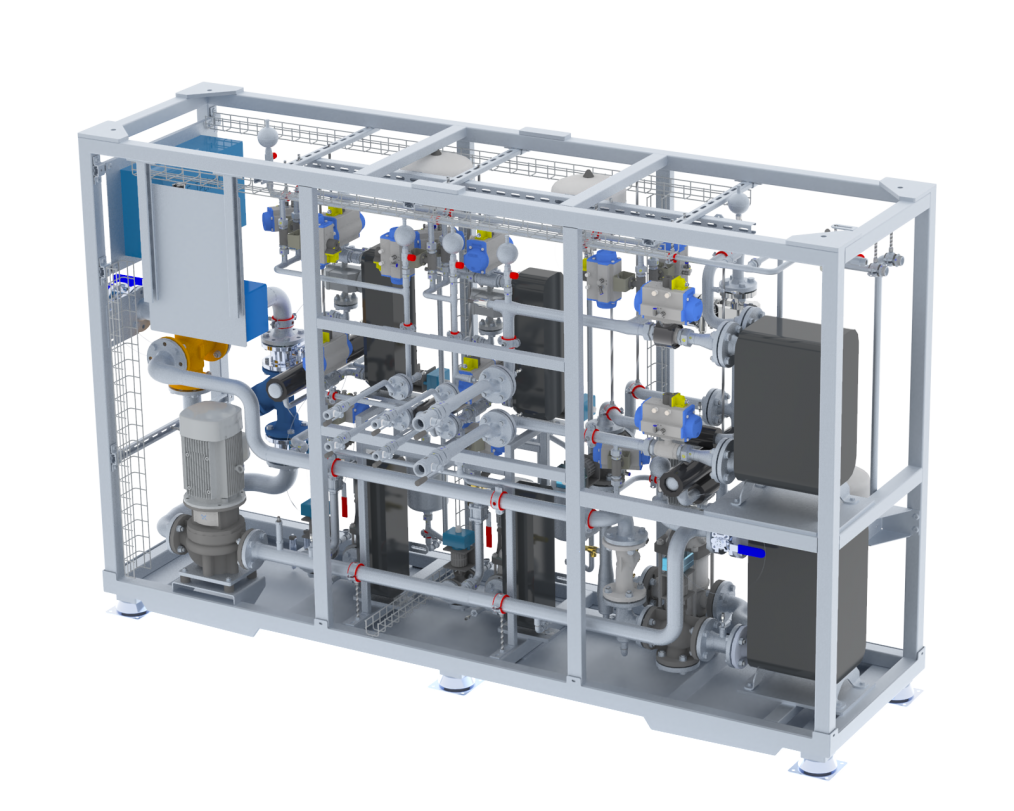

Dynamic and accurate control of pressure, temperature and humidity of process factors by model based control technique and smart rig design.

Future mobility will be based on a colourful mix of fuels and drive concepts, and hydrogen-powered fuel cells will play an important role. KS test beds for fuel cells offer the necessary flexibility to deal with the most diverse scenarios and the resulting testing tasks. System features such as KS DPC (Dynamic Pressure Control) allow independent and highly accurate pressure control of process supply and extract air. Fuel cells and complete fuel cell-driven vehicles can be put through their paces in the high-performance temperature chamber, with extensive safety technology ensuring the safe operation of the system when doing so.