R2R Road to Rig

In-house application

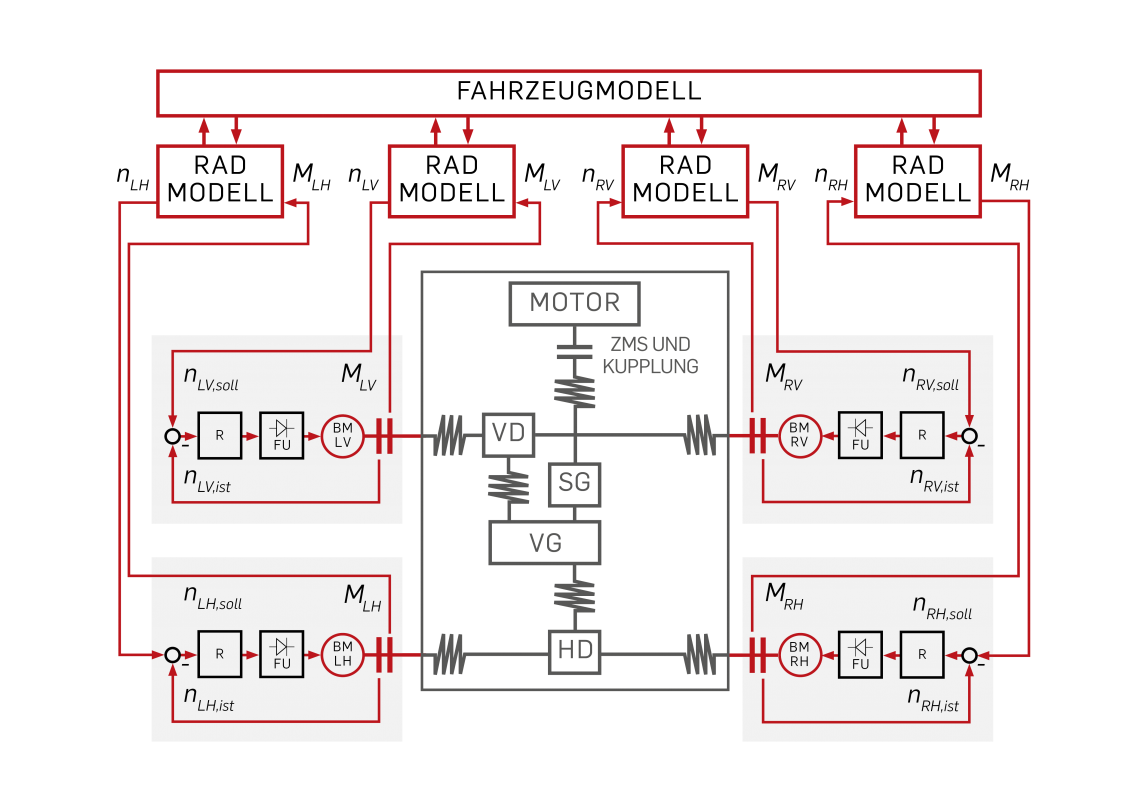

In-house vehicle testing and application under real driving conditions. Integration of vehicle, road and tyre model, testing and tuning of driver assistance systems.

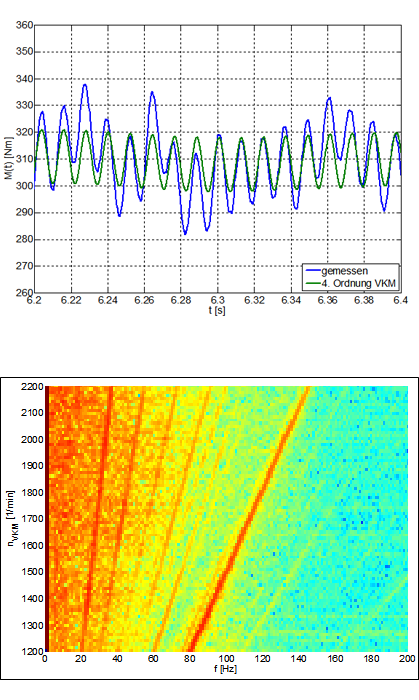

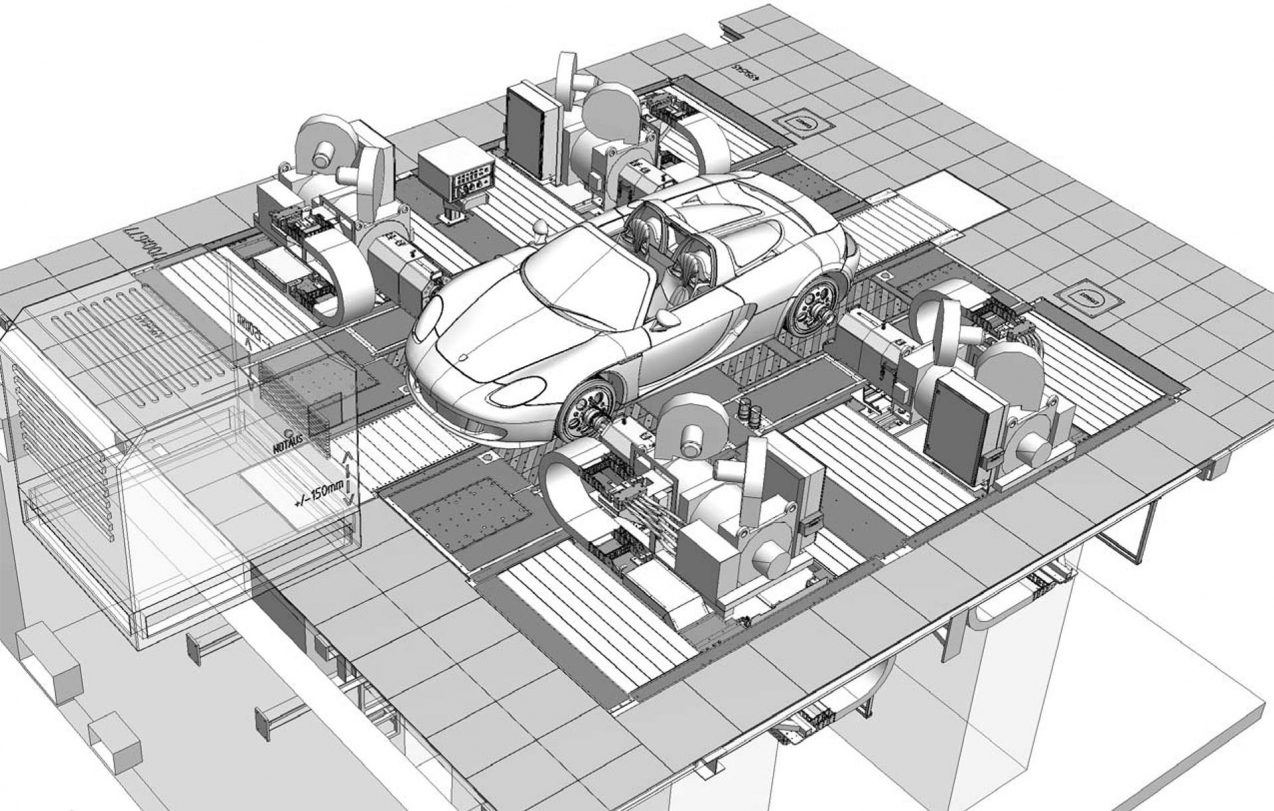

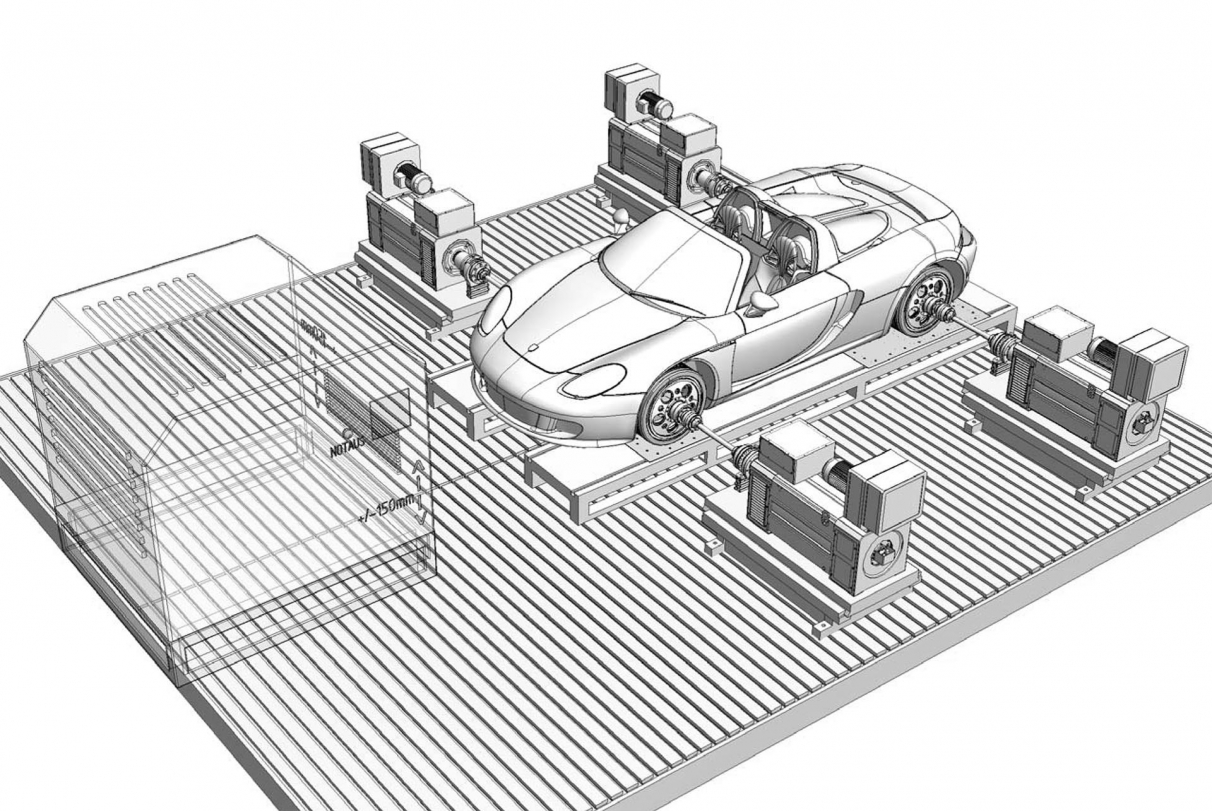

Ever shorter innovation cycles in developing new, complex drive systems, such as automatic or hybrid transmissions, previously meant that extensive, time-consuming tests and trials had to be performed on the road. The KS-R2R 4x4 test rig has now revolutionised testing. Testing of complete powertrains can therefore be shifted to the test bed at every stage of development. We have thus achieved three strategic goals: improving the quality of development services, substantially reducing the development costs and significantly saving on development time.

Given the revolutionary inertia compensation system, any powertrains from small cars to SUVs can be tested on one and the same rig without having to change the setup. The unit under test is thus subjected to identical conditions as in real road testing. You can configure any type of roads and surfaces on the KS R2R 4x4’s host computer - such as dry, rainy or snowy conditions.

Carrying out special misuse tests is also possible: idiot start, parking lock and chessboard tests, turning with the hand brake on, manhole covers, off-road driving and much more. As an alternative to frontloading real test drives, native data acquired from simulation programs (e.g. win-EVA, CarMaker, ve-DYNA) can also be used as references.

This now also enables test configurations that could not previously be simulated on test beds: for example real drivetrains in combination with virtual bodies. With the extremely user-friendly KS-R2R you can therefore test the powertrain’s true behaviour throughout the entire development process: independently of time, place and weather conditions, reproducing tests and changing parameters as you require.